Molybdenum powder rubber rod turning and pouring mechanism

A glue stick and pouring technology, which is applied in the field of molybdenum powder glue stick flipping and pouring mechanism, can solve the problem of uneven distribution of molybdenum powder in the length direction, and achieve the effects of saving time, reducing costs and ensuring durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

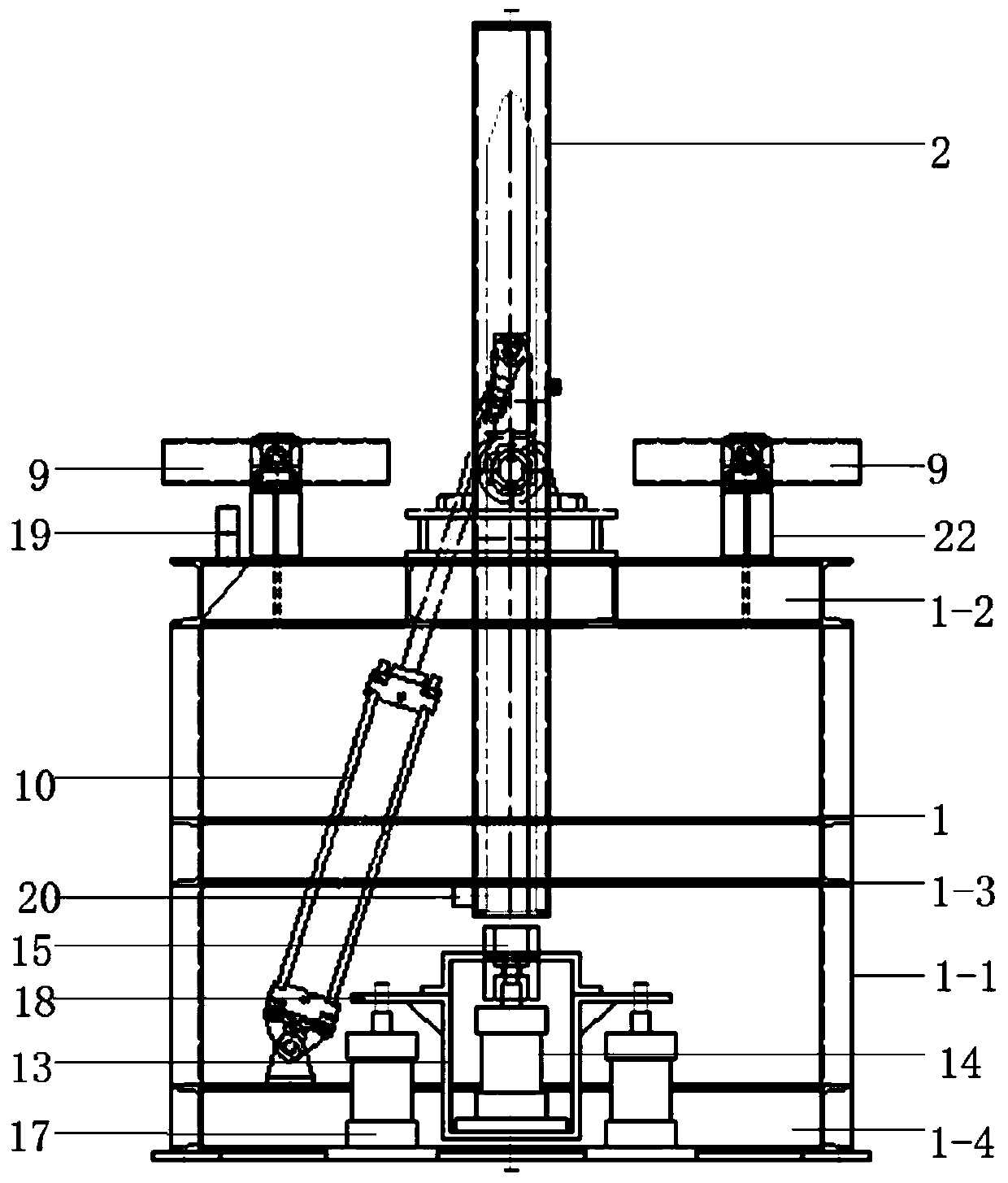

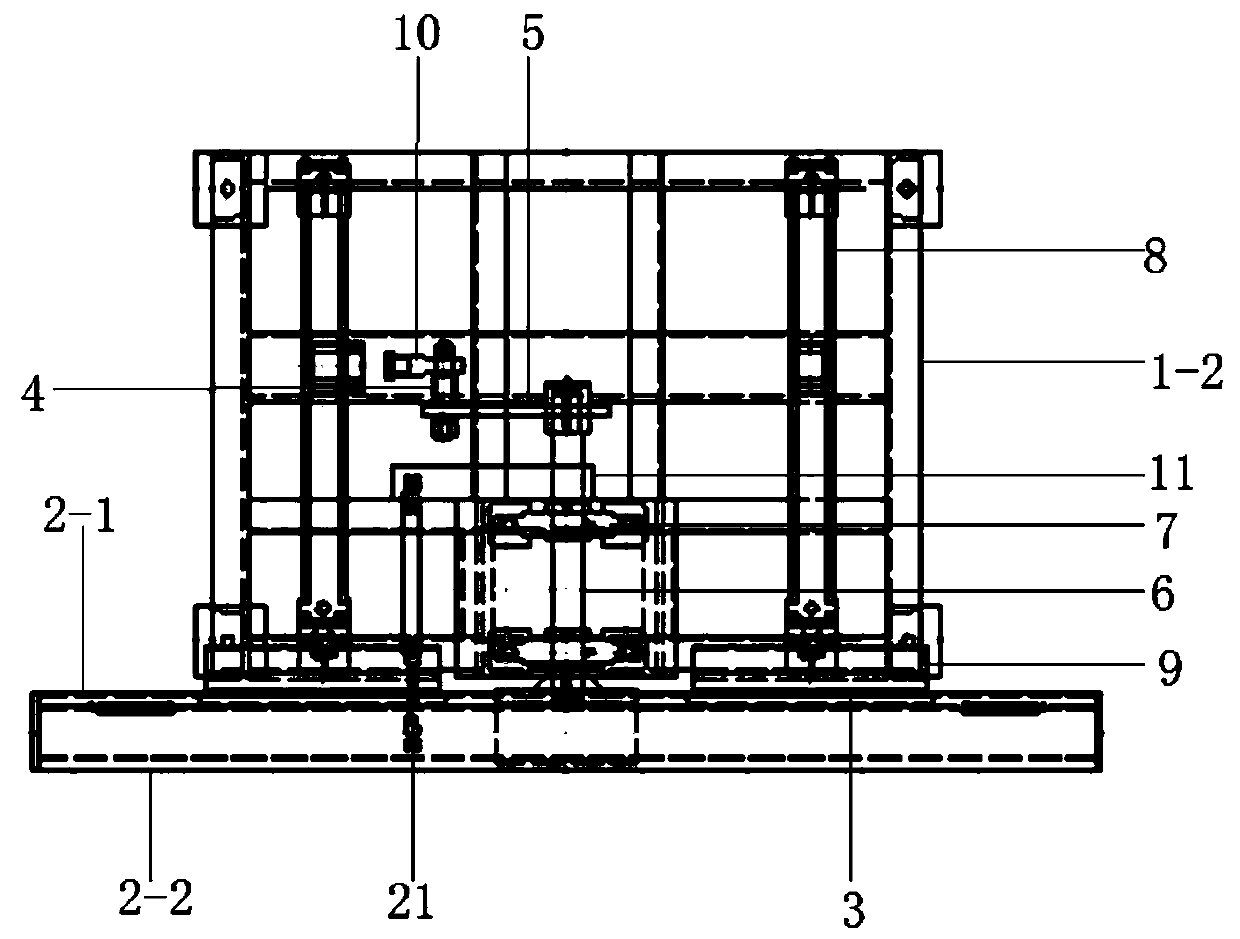

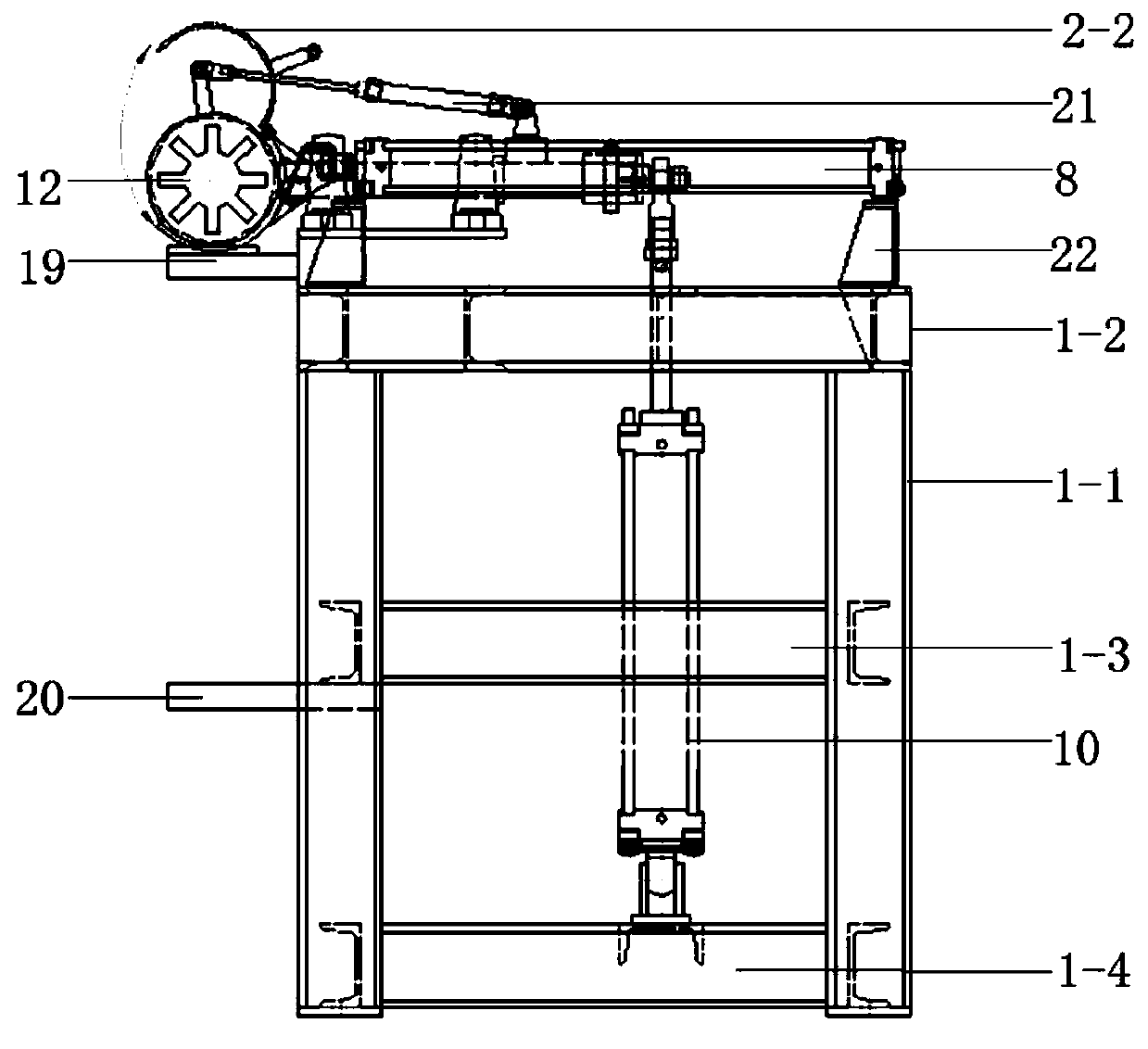

[0021] A kind of molybdenum powder glue stick flipping and discharging mechanism of the present invention, such as figure 1 As shown, it includes a frame 1 and a turning cylinder 2. The frame 1 includes a bracket 1-1, on which a frame a1-2, a frame b1-3 and a frame c1-4 parallel to each other are fixed from top to bottom. The frame c1-4 is provided with a driving device for turning over the turning cylinder 2, and the turning cylinder 2 is divided into a cylinder body 2-1 and a switch cover 2-2, and the cylinder body 2-1 and the switch cover 2-2 are hinged, such as figure 2 and image 3 As shown, two pushing grooves 3 are arranged symmetrically on the cylinder body 2-1, and the pushing grooves 3 are directly opposite to the pushing device. The frame a1-2 is fixed with a pushing device for pushing out the inner glue stick of the cylinder bo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap